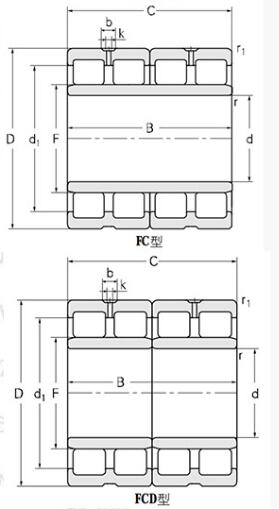

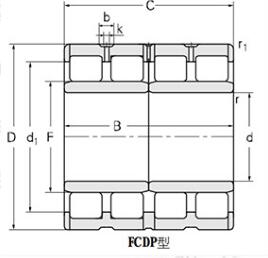

Four-row cylindrical roller bearings come in various structural designs. The main design differences between bearings are the number of inner and outer rings, the inner ring design (flange structure), and the design and material of the cage. Common structures are shown in the figure below.

Since four-row cylindrical roller bearings can only carry radial loads, they are installed with deep groove ball or angular contact ball bearings, or with tapered roller bearings (radial or thrust design) that bear axial loads.

Because of the large number of rollers, four-row cylindrical roller bearings are suitable for very high radial loads. The open flange design, combined with the roller end face design and surface treatment, promotes the formation of a lubricating film to reduce friction and improve axial load carrying capacity. The components of four-row cylindrical roller bearings are separable and interchangeable. This facilitates installation, disassembly, and maintenance inspection. Cage designs are suitable for high speeds, rapid acceleration, and impact loads. The lower cross-sectional height of four-row cylindrical roller bearings allows for the use of larger roller necks compared to the roller diameter.

Four-row cylindrical roller bearings are primarily used in the roll necks of rolling mill stands, finishing mills, and rolling mills. Because these bearings are typically installed with an interference fit on the roll neck, four-row cylindrical roller bearings are particularly suitable for high-speed rolling mill applications.

The structure, dimensions, designation method, dimensional tolerances, radial clearance, and other related technical requirements of domestically produced four-row cylindrical roller bearings should comply with JB/T5389.1-2016 standard.

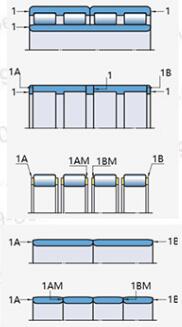

The components of a four-row cylindrical roller bearing must be installed in the correct order. Therefore, bearing manufacturers have taken several precautions to simplify installation:

1. Components belonging to the same group are marked accordingly. See the example below.

2. All components of each bearing are marked with the same serial number to reduce the risk of component confusion.

3. If the two inner rings are completely interchangeable, they do not need to have the same numbering as the outer rings.

If the tapered bore bearing is installed with an interference fit, the bearing can be adjusted during installation to obtain a certain radial internal clearance or a defined preload.

In most applications, the load is directional, so only about a quarter of the outer ring bears the load. Therefore, the following precautions should be taken: The outer ring side is divided into four zones, I through IV.

Zone 1 also includes a line running through the outer surface of the bearing.

Zone 1 should be positioned in the direction of the load for initial installation.

After a certain service life, the outer ring should be rotated 90°, depending on operating conditions. The recommended service life is approximately 1000 operating hours, after which the bearing should be inspected.

CQBB Four-Row Cylindrical Roller Bearings:

http://yihao-jiaju.cn/en/products/Four-row-Cylindrical-Roller-Bearings(for-rolling-mill)/1048.html

2025-12-08